Introduction

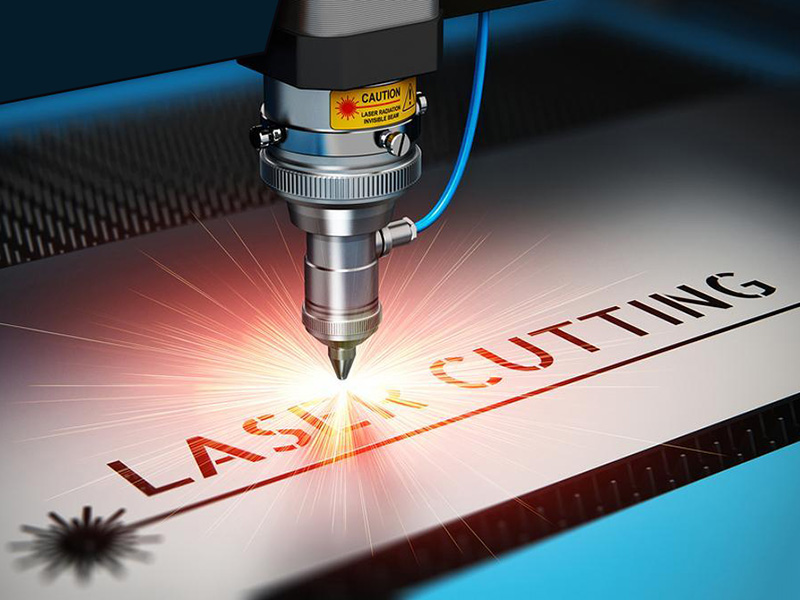

Laser cutting has revolutionized many industries with its precision, speed and versatility. From intricate jewelry designs to large industrial components, laser cutting machines have become indispensable tools. We can often see exquisite laser cut pieces on Amazon or other platforms, often working on materials that are tough.

Meanwhile, vinyl, derived from PVC (polyvinyl chloride), has gained immense popularity in arts, crafts, signage, and various other applications due to its durability and resistance to heat and moisture. However, the central question remains: can vinyl be safely laser cut?

What is Laser cutting, And What is Vinyl?

Laser Cutting Process

Laser cutting involves a computer-controlled laser beam that directs intense energy onto a material, causing it to melt, vaporize, or burn. This technology is capable of engraving, etching, or cutting through a wide range of materials with remarkable accuracy.

Vinyl as a Material

Vinyl, being made from PVC, offers a blend of durability and flexibility. Its resistance to heat, moisture, and wear makes it ideal for signage, decals, and numerous other applications. However, these properties also introduce specific challenges when considering laser cutting.

Can You Laser Cut Vinyl? Risks and Challenges

While technically it is possible to laser cut vinyl, it is generally not recommended. The PVC in vinyl releases toxic chlorine gas and hydrochloric acid when heated by a laser. These emissions pose significant health risks, including respiratory issues, eye irritation, and potential long-term harm.

Additionally, the acid fumes can corrode the laser machine, leading to premature wear and tear. From an aesthetic perspective, laser-cut vinyl often exhibits burnt edges and discoloration, compromising the final appearance.

Safer Alternatives and Methods

Laser-Safe Vinyl Options

To avoid the risks associated with laser cutting PVC-based vinyl, consider using PVC-free alternatives. Materials like PEVA (polyethylene vinyl acetate), PVB (polyvinyl butyral), PVA (polyvinyl alcohol), or proprietary non-toxic vinyl can be labeled as "laser-safe" and are designed to minimize harmful emissions when exposed to laser energy.

Choosing the Right Laser

If you must use laser cutting with vinyl, opt for diode lasers, which generate lower heat compared to CO₂ lasers. Diode lasers pose a reduced risk of toxic emissions and machine damage, though they are still not ideal for standard PVC vinyl.

Blade Cutting as a Safer Alternative

Blade cutting offers a safer and more aesthetically pleasing alternative to laser cutting vinyl. This method involves no heat, thereby eliminating the risk of toxic fumes. Blade cutting produces clean cuts without burn marks, making it ideal for thin materials like vinyl, paper, and fabric.

Choose Likcut's vinyl cutter for the safest and most stable way to cut vinyl while significantly reducing the cost of creating vinyl pieces. The Likcut S501 is suitable for all small home-style vinyl projects, click the link to choose your purchase.

5. FAQs

Can you laser cut PVC vinyl?

No. PVC releases toxic fumes when heated by a laser, posing significant health and safety risks.

What vinyl is safe for laser cutting?

PVC-free, chlorine-free variants that are explicitly labeled "laser-safe" are suitable for laser cutting.

Can diode lasers cut vinyl?

Yes, but only with laser-safe vinyl. Even with diode lasers, it is crucial to use materials specifically designed for laser cutting.

Can vinyl records be laser cut?

No. Vinyl records contain PVC and laser cutting would risk damaging the audio grooves, rendering them unusable.

Conclusion

In summary, while laser cutting offers numerous benefits, it is not advisable to use it on standard PVC vinyl due to the health and safety hazards associated with toxic emissions. If laser cutting is necessary, opt for laser-safe vinyl alternatives and ensure proper personal protective equipment (PPE) and ventilation are in place.

However, blade cutting remains the recommended method for working with vinyl, offering clean cuts without the risks associated with laser cutting. By understanding the limitations and alternatives, you can make informed decisions to ensure your projects are both successful and safe.